We source the high quality raw materials used to produce our products from BAOSTEEL, TISCO, DAMING, TPCO, TSINGSHAN, JIULI, WUJIN, and STELLAR and so on.

In the production of welded pipe fittings and seamless pipe fittings which are processed by our hot forming machines or cold forming machines, we rigorously follow a complete set of processes, including material feeding, forming, heat treatment, sheet metal processing, nondestructive testing,end beveling, surface treatment, marking, final inspection, and delivery.

YANGZI has accumulated about 30 years of experience in the production of large size welded pipe fittings. Large forming molds feature complete range of sizes from 6 inches to 100 inches. We have equipped our facilities with a powerful 1500-ton press machine matching with the working platform of 3.5 x 2.2 meters. At the end of 2017, we will introduce a 3000-ton press machine with a working platform of 5 x 3.5 meters to improve production efficiency and press quality.

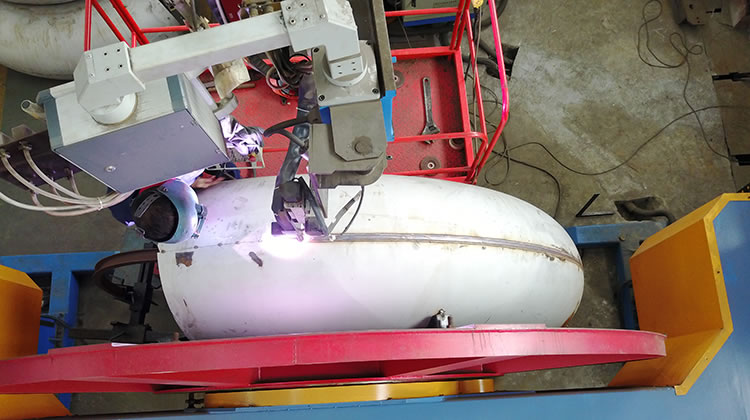

The heat treatment solution improves the plasticity and toughness of the pressed materials and eliminates stress. After the edges of pipe fittings are milled, two pieces of half round pipe fittings are welded by hot forging and submerged arc welding. Yangzi is equipped with manual welding, semi-automatic and fully automatic welding equipments, we provide arc welding, argon arc welding, submerged arc welding, gas shielded welding, plasma welding.

The formed pipe fittings are further processed under grooving operations before going through surface treatment. Single Beveling Machines Area, Double Beveling Machines Area, we can process all kinds of bevels types as per ASTM, DIN, JIS, ETC.

Our advanced X-ray detection equipment strictly monitors the quality of large-size welded pipe fittings. The detection capacity can reach up to 65mm in depth in our factory.

YANGZI’s cold forming workshop completes the production of seamless pipe fittings made of stainless steel, duplex stainless steel,super duplex stainless, aluminum, copper and other non ferrous metal materials. Three elbow cold forming machines are used to process elbows with sizes from 1/2 inch to 20 inch. The maximum wall thickness of the cold forming elbow reaches Sch80. The elbows produced by this equipment possess a high pass rate. The back thinning rate is slightly reduced. The production equipment operates automatically for mass production of the pipe fittings with the same specification to ensure the uniformity of the products. The cold forming processes are including materials loading, mould pressing, mandrel pushing, ejecting, stripping, etc.

It will take around 10 minutes to produce one 20” Elbow.

The finished products will go through a series of processes before packaging and delivery, including hardness examination, wall thickness examination, visual&dimensional examination,PMI examination,dye penetrant examination, angle examination,MT examination,inkjet printing, etc.

Our raw materials warehouse covers an area of 2000 square meters. The steel plates are supplied by domestic famous steel mills, including Baosteel, Anshan Iron & Steel, and JINAN Iron & Steel. Some of the raw materials are imported from Outokumpu.

Raw material warehouse

Raw material warehouse

The plasma flame cutting machine covers an area of 60 square meters. It can cut the steel plate with the maximum wall thickness of 150mm, the maximum width of 3.2 m, and the length of 12.5m.

Plasma flame cutting machine

Plasma flame cutting machine

The 2000-square-meter hot pressing workshop processes half elbows with a maximum diameter of 100 inches. It also manufactures molded pipe tees with a maximum diameter of 56 inches and welded pipe tees with a maximum diameter of 100 inches.

Hot pressing workshop

Hot pressing workshop

The 1500-ton press machine produced by Shanghai High Pressure Container Co., Ltd. is equipped with a working platform with length of 3.5 meters and width of 3 meters. The 1500-ton press machine works with the press mold to process the pipe elbows with the maximum size of 100 inches and wall thickness of 100 mm.

1500-ton press machine

1500-ton press machine Sheet stamping

Sheet stamping

The sizes of our elbow manufacturing molds range from 6 inches to 100 inches. The maximum size of pipe tee molds is 56 inches.

Large-size pressing mold

Large-size pressing mold

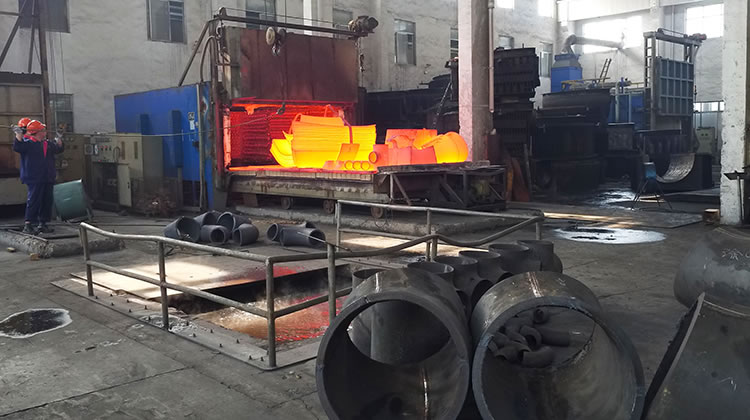

Our three electric furnaces and one gas stove finish heat treatment of all products of various materials, including normalizing, tempering, quenching, annealing and so on.

Solution heat treatment

Solution heat treatment Opening furnace for cooling

Opening furnace for cooling

When the steel plates are pressed to have particular forms, they are processed again by edge milling machine. The maximum size of the pressed steel plates is 100 inches and the maximum wall thickness is 150mm.

Edge milling

Edge milling

We are equipped with 3 double head chamfering machines to finish processing of products with sizes ranging from 1/2 inch to 16 inches, and the maximum wall thickness is 40mm.

Our 5 single head chamfering machines can process products with sizes from 6 inches to 100 inches, and the maximum wall thickness is 100 mm.

Automatic welding machine

Automatic welding machine Submerged arc welding

Submerged arc welding Double head chamfering machine

Double head chamfering machine Single head chamfering machine

Single head chamfering machine

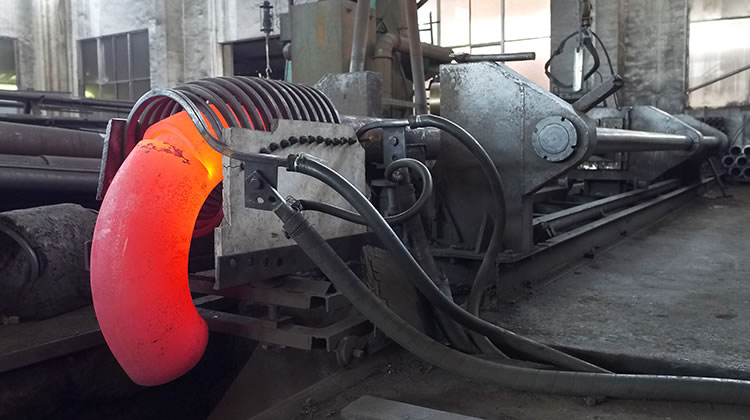

Processing of seamless elbow by hot forming machine

Processing of seamless elbow by hot forming machine

There is 1 pipe tee cold forming machine in the cold forming workshop to process pipe tees with a maximum size of about 27 cm. 3 pipe elbow cold forming machines are able to process pipe elbows with a maximum size of 67 cm, and the maximum wall thickness of the pipe elbows is Sch80. These equipment can manufacture seamless pipe fittings, such as stainless steel pipe fittings, duplex steel pipe fittings, aluminum pipe fittings and copper pipe fittings and so on,

Hot forming workshop

Hot forming workshop

The fully automatic sawing machine in the cold forming workshop cuts steel pipes with a maximum size of about 80 cm.

Fully automatic sawing machine

Fully automatic sawing machine

Stainless steel elbow cold forming machine YLT100B features quick molding speed. The single stainless steel elbow can be finished within 15-45 seconds. The pass rate of the qualified steel elbow is high. The wall thickness of rear pipe is slightly reduced, so it meets the requirements for product tolerance.

Stainless steel elbow cold forming machine YLT100B

Stainless steel elbow cold forming machine YLT100B Elbows with sizes of 1/2—4 inches

Elbows with sizes of 1/2—4 inches

Stainless steel elbow cold forming machine YLT250B is able to process pipe elbows with sizes ranging from 4 inches to 10 inches (DN100到DN250) and wall thicknesses from Sch10s to Sch XXS. According to different wall thicknesses, the processing of single pipe elbow needs 45 seconds to 150 seconds. The stainless steel elbow cold forming machine YLT250B can be operated by one operator and it has high operating efficiency.

Stainless steel elbow cold forming machine YLT250B

Stainless steel elbow cold forming machine YLT250B

The stainless steel elbow cold forming machine processes pipe elbows with sizes of 12 -- 20 inches (DN300 to DN500), and the wall thickness ranges from Sch10 to Sch 80. It has a high production capacity. The stainless steel elbow cold forming machine can automatically manufacture pipe elbows with the same specifications. It operates without noise and odor.

Stainless steel elbow cold forming machine YLT500B

Stainless steel elbow cold forming machine YLT500B Demolding of finished elbows

Demolding of finished elbows

Automatic welder in cold forming workshop

Automatic welder in cold forming workshop Top view of welding operation

Top view of welding operation

The 60-square-meter exposure testing room with directional and axial X-ray machines is established for X-ray detection of large size pipe fittings. The detection capacity can reach up to 65mm in depth, which covers depth of most products.

X-ray detection

X-ray detection

We have a complete range of testing equipment, including the laser inkjet printer, thickness gauge, vernier caliper, micrometer, direct reading spectrometer, hardness tester, and magnetic powder detection device. All the products’ testing reports are archived for over 5 years.

Finished products testing and packaging

Finished products testing and packaging Various instruments for testing

Various instruments for testing

Wood floors prevent abrasions of the pipe fittings. The pipe fittings are packed by pallets or plywood boxes.

Large size pipe elbows for export to Iran

Large size pipe elbows for export to Iran Packaging of pipe elbow before being packed in plywood box

Packaging of pipe elbow before being packed in plywood box

Jiangyin Yangzi Fitting Co.,Ltd.

Add.: No. 168, Panlongshan Rd., Shanguan Town, Jiangyin City, Jiangsu Province, China

Contact person: Mr. Zhou

Tel.: +86-510-86996585-8017

Fax.: +86-510-86992666